Dulmar

304 steel waa nooc ka mid ah walxaha birta ah ee caalamiga ah, caabbinta miridhku waa ka xoog badan tahay 200 taxane ah oo ah walxaha birta ah, iska caabbinta heerkulka sare ayaa sidoo kale ka fiican, waxay noqon kartaa ilaa 1000-1200 digrii. iska caabin daxalka.Waxa kale oo uu leeyahay iska caabin daxalka wanaagsan in xal alkaline iyo inta badan organic iyo inorganic acids.

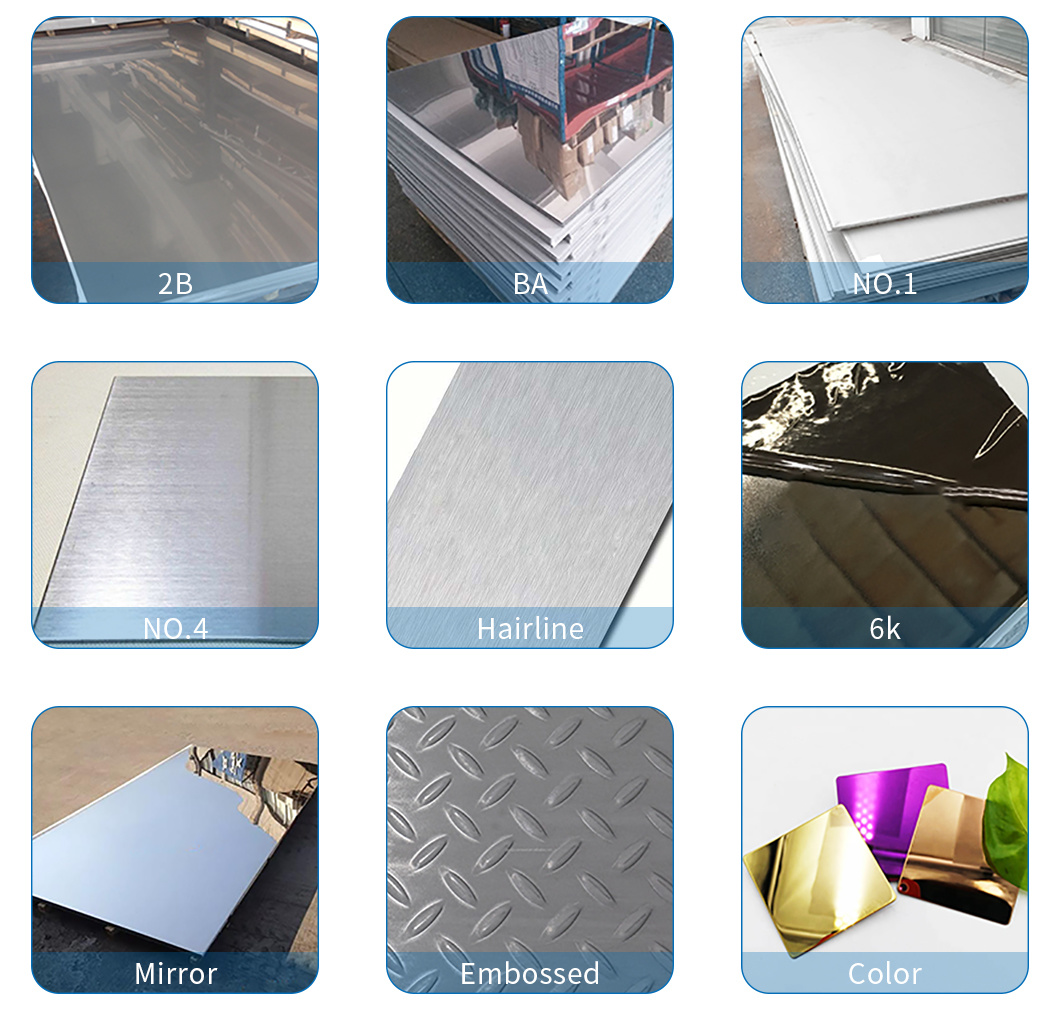

Tilmaamid

| Dhamaystir dusha sare | Sharaxaada |

| 2B | Dhammaadka dhalaalaya, ka dib duubista qabow, daawaynta kulaylka, ayaa si toos ah loo isticmaali karaa, ama tallaabo horudhac ah oo lagu nadiifinayo. |

| 2D | Dusha caajiska ah, taas oo ka dhalata rogrogan qabow oo ay ku xigto xoqid iyo xoqid. Waxa laga yaabaa inay hesho duubka ugu dambeeya ee nalka oo ka soo dhex mara duubab aan la daabicin. |

| BA | Dhamaystir dhalaaleed oo dhalaalaya kaas oo lagu helo in la tirtiro walxaha jawiga hoostiisa si miisaanku aanu u soo saarin dusha sare. |

| No.1 | Dhammays adag, caajis ah, taas oo ka dhalata duubid kulul ilaa dhumucda la cayimay. Waxaa ku xiga ciribtirka iyo dhimista. |

| No.3 | Dhamaystirkan waxa lagu sifeeyay No.100 ilaa No.120 abrasive ku qeexan JIS R6001. |

| No.4 | Dhamaystirkan waxa lagu sifeeyay No.150 ilaa No.180 abrasive ku qeexan JIS R6001. |

| Timaha timaha | Dhamaystir qurux badan, oo lagu ilaaliyo filimka PVC ka hor inta aan la isticmaalin, loo isticmaalo qalabka jikada, |

| 8K muraayad | "8" ee 8K waxa ay tilmaamaysaa saamiga qaybaha daawaha (304 birta aan lahayn badiyaa waxa ay tilmaamaysaa waxa ku jira curiyeyaasha), "K" waxa ay tilmaamaysaa heerka milicsiga ka dib dhalaalid. Dusha muraayadda 8K waa heerka muraayadda oo ay ka muuqato birta nikkel ee chrome. |

| Isku duuban | Waraaqaha birta ah ee dhejiska ah waa walxo badan oo loo isticmaalo in lagu abuuro saameyn qurxinta dusha birta. Waxay door fiican u yihiin mashaariicda dhismaha, dib-u-dhacyada, calaamadaynta, iyo in ka badan. Aad bay u fudud yihiin, waxaana loo qaabayn karaa inay buuxiyaan shuruudaha codsiyada kala duwan. |

| Midabka | Birta Midabka leh waa titanium-ka dahaarka leh ee aan lahayn birta. Midabada waxaa lagu helaa iyadoo la isticmaalayo habka PVD. Foomamka ku yaal dusha xaashi kastaa waxay bixiyaan noocyo kala duwan oo daahan ah, sida oxides, nitrides iyo carbides. |

Isticmaalka ugu muhiimsan waa

1. Used si loogu habeeyo dhammaan noocyada qaybaha caadiga ah iyo shaabadeynta dhinta;

2.Used sida qaybaha farsamada saxda ah ee birta;

3. Waxaa si weyn loogu isticmaalaa habka daaweynta kulaylka ee ka saarista cadaadiska ka hor inta aan la foorarrin.

4. Waxaa loo isticmaali karaa sidii qalab dhisme oo loogu talagalay dhismaha madaniga ah.

7. Waxa loo isticmaali karaa warshadaha baabuurta.

8. Waxaa lagu dabaqi karaa warshadaha qalabka guriga. Qaybta tamarta nukliyeerka. Hawada iyo duulista. Qalabka korantada iyo korontada. Warshadaha mishiinada caafimaadka. Warshadaha dhismaha maraakiibta.

Isku-dhafka Kiimikada ee Birta Aan-La-aanta ah ee Caadiga La Isticmaalo

| Darajo | C | Si | Mn | P | S | Ni | Cr | Mo | Kuwo kale |

| 304 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 17.5/19.5 | - | N≤0.10 |

| 304H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | - | |

| 304L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 17.5/19.5 | - | N≤0.10 |

| 304N | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | - | N:0.10/0.16 |

| 304LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 18.0/20.0 | - | N:0.10/0.16 |

| 309S | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 12.0/15.0 | 22.0/24.0 | - | |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0/22.0 | 24.0/26.0 | - | |

| 316 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | |

| 316LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N:0.10/0.16 |

| 317L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N≤0.10 |

| 317LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N:0.10/0.22 |

| 321 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/12.0 | 17.0/19.0 | - | N≤0.10Ti:5ʷʢC+Nʣ/0.70 |

| 347 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/13.0 | 17.0/19.0 | - | Nb:10ʷC/1.00 |

| 904L | ≤0.020 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0/28.0 | 19.0/23.0 | 4.00/5.00 | N≤0.10Cu:1.0/2.0 |

-

201 304 Midabka birta aan-Aamiga ahayn ee muraayada ee S...

-

316L 2B xaashida birta ah ee la hubiyay

-

304 Midabaysan oo xaashida birta ah oo xoqaya taarikada

-

430 xaashi bir ah oo daloolsan

-

SUS304 xaashida birta ah ee xardhan

-

201 J1 J3 J5 Xaashiyaha Biraha Aanay Ahayn

-

Waraaqaha birta ah ee aan daloolin

-

PVD 316 xaashida birta ah ee midabka leh

-

SUS304 BA Heerka ugu Wanaagsan ee xaashida birta ah ee aan lahayn

-

SUS316 BA 2B Alaab-iibiyaha xaashida birta ah ee bilaa birta ah