Heerka Sare ee Saxanka Kaarboon Kaarboon

| ASTM A283/A283M | ASTM A573/A573M | ASME SA36/SA36M |

| ASME SA283/SA283M | ASME SA573/SA573M | EN10025-2 |

| EN10025-3 | EN10025-4 | EN10025-6 |

| JIS G3106 | DIN 17100 | DIN 17102 |

| GB/T16270 | GB/T700 | GB/T1591 |

U soo qaado codsiyada A36 tusaale ahaan

Codsiga ASTM A36 Kaarboon Qaab-dhismeedka Birta

| Qaybaha Mashiinada | Frames | Qalabka | Taarikada wax lagu dhejiyo | Haamaha | Biinanka | Taarikada wax lagu dhejiyo | Been abuurasho |

| Taarikada Saldhigga | Gears | Kaamirooyinka | Sprockets | Jigsasho | Silsilad | Qaababka | Qalabka |

| ASTM A36 Xulashada Saxanka Birta | |||||||

| Laabicidda Qabow | Samaynta Kulul khafiif ah | Feer | Makiinada | alxanka | Laabicidda Qabow | Samaynta Kulul khafiif ah | Feer |

Halabuurka Kiimikada ee A36

| ASTM A36 Saxan Bir ah oo Kulul | Isku-dhafka Kiimikada | |

| Curiyaha | nuxurka | |

| Kaarboon, C | 0.25 - 0.290 % | |

| Copper, Ku | 0.20% | |

| Birta, Fe | 98.0% | |

| Manganese, Mn | 1.03% | |

| Fosfooraska, P | 0.040% | |

| Silikoon, Si | 0.280% | |

| Sulfur, S | 0.050% | |

Hantida Jirka ee A36

| Hanti Jireed | Metric | Imperial |

| Cufnaanta | 7.85 g/cm3 | 0.284 lb/in3 |

Hantida makaanikada ee A36

| ASTM A36 Qalabka Birta La Dulmaray ee Kulul | ||

| Guryaha Makaanikada | Metric | Imperial |

| Xoog-jiidka, Ugu Dambeeya | 400 - 550 MPa | 58000 - 79800 psi |

| Xoogga Jilitaanka, Wax-soosaarka | 250 MPa | 36300 psi |

| Kordhinta xilliga Nasashada (200 mm gudahood) | 20.0% | 20.0% |

| Kordhinta xilliga Nasashada (50 mm gudahood) | 23.0% | 23.0% |

| Qaabka Elasticity | 200 GPA | 29000 ksi |

| Modulus Bulk (caadi ahaan birta) | 140 GPA | 20300 ksi |

| Saamiga Sunta | 0.260 | 0.260 |

| Modul jeex | 79.3 GPA | 11500 ksi |

Birta kaarboonku waa alloy ka kooban bir iyo kaarboon. Dhowr walxood oo kale ayaa loo oggol yahay birta kaarboonka, oo leh boqolkiiba ugu badnaan hooseeya. Curiyayaashani waa manganese, oo leh 1.65% ugu badnaan, Silicon, oo leh ugu badnaan 0.60%, iyo naxaas, oo leh ugu badnaan 0.60%. Cutubyo kale ayaa laga yaabaa inay joogaan tiro aad u yar oo saameyn ku yeelan kara hantidooda.

Waxaa jira afar nooc oo birta kaarboon ah

Iyada oo ku saleysan qaddarka kaarboonka ee ku jira daawaha. Biraha kaarboonka hoose waa kuwo jilicsan oo si fudud u samaysan, biraha kaarboonku ku badan yahayna way adag yihiin oo way ka xoog badan yihiin, laakiin way ka yar yihiin, waxayna noqdaan kuwo aad u adag in la isticmaalo iyo alxanka. Hoos waxaa ah sifooyinka darajooyinka birta kaarboon ee aanu bixino:

● Birta Kaarboon-hooseeya–Kaarboonka 0.05%-0.25% iyo ilaa 0.4% manganese. Sidoo kale loo yaqaan birta khafiifka ah, waa shay qiimo jaban oo ay fududahay in la qaabeeyo. In kasta oo aanay u adkeyd sida biraha kaarboon-sare ee kaarboonka, aasidda baabuurka waxay kordhin kartaa adkaanta dusha sare.

● Birta Kaarboon Dhexdhexaadka ah - Kaarboonka 0.29%-0.54%, oo leh 0.60%-1.65% manganese. Birta kaarboon dhexdhexaadka ah waa ductile waana xoog badan tahay, oo leh sifooyin dhaadheer.

● Birta Kaarboonka Sare-Kaarboonka 0.55%-0.95%, oo leh 0.30%-0.90% manganese. Aad bay u xoog badan tahay waxayna si fiican u haysaa xusuusta qaabka, taas oo ka dhigaysa mid ku habboon ilaha iyo fiilooyinka.

● Birta Kaarboon aadka u Saraysa - Kaarboonka 0.96%-2.1% ka kooban. Kaarboonka ku jira ee sarreeya ayaa ka dhigaya walxo aad u xoog badan. Jilicsanaantiisa awgeed, darajadan waxay u baahan tahay maarayn gaar ah.

Sawir faahfaahsan

-

A36 Hot Rolled Steel Plate Warshada

-

Q345, A36 SS400 Gariiradda Birta ah

-

Qalabka birta ah ee ASTM A36

-

ASTM A653 Z275 Galvanized Steel Coil Warshada Shiinaha

-

S355 Qaab-dhismeedka Birta Birta

-

S355G2 Saxanka Birta Badda

-

S355J2W Corten Plates Weathering steel Plates

-

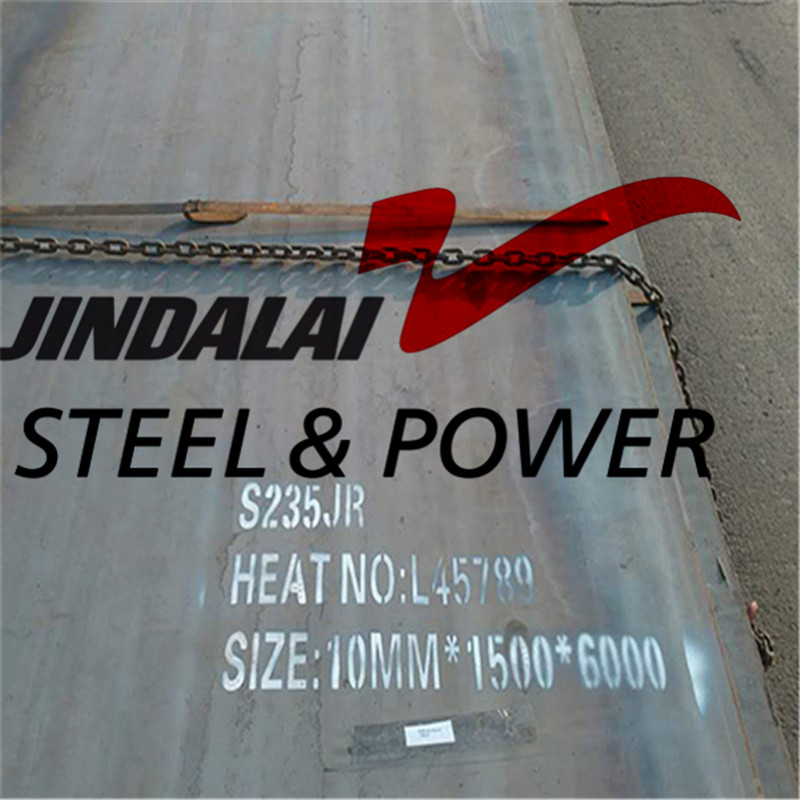

S235JR Taarikada Birta Kaarboon/MS Plate

-

SS400 Q235 ST37 gariiradda birta ah ee duuban ee kulul

-

Saxanka birta ee la hubiyay

-

Saxan bir saxan oo galvanized ah oo kulul

-

BIRTA FUDUD (MS) saxan la hubiyay

-

Gariiradda Hubinta La Dulmaray ee Kulul/Ms Checkered Coils/HRC