Dulmar guud ee dhuumaha birta daawaha

Dhuumaha birta Alloy waxaa loo isticmaalaa codsiyada u baahan guryaha iska caabbinta daxalka dhexdhexaad ah oo leh adkeysi wanaagsan iyo kharash dhaqaale. Si fudud loo dhigo, tuubooyinka daawaha ayaa la door bidaa meelaha tuubooyinka birta ee kaarboonku ay fashilmi karaan. Waxaa jira laba nooc oo birta daawaha ah - Alloys sare iyo birta daawaha hoose. Tubooyinka ka kooban birta daawaha hoose waxay leeyihiin maaddooyin alloying oo u dhexeeya 5%. Halka maadada daawaynta ee birta daawaha sare u dhaxayso 5% ilaa 50%. Si la mid ah inta badan Alloys-ka awoodda cadaadiska shaqada ee Alloy Steel Tubta aan Xumaan lahayn waxay ku saabsan tahay 20% ka sarreeya tuubada alxanka. Sidaa darteed codsiyada leh cadaadis shaqo oo sarreeya sida shardi ahaan, isticmaalka tuubo aan fiicneyn ayaa xaq ah. In kasta oo uu ka xoog badan yahay tuubada alxanka, qiimuhu aad buu u sarreeyaa. Intaa waxaa dheer, khatarta daxalka intergranular ee aagga alxanka ee kuleylku saameeyay waxay ku badan tahay alaabta alxanka ah. Farqiga muuqda ee u dhexeeya birta alxanka leh ee Alloy Steel iyo badeecada aan kala go 'lahayn waa tolitaanka latitude ee dhererka tuubada. Si kastaba ha ahaatee, maanta, iyada oo horumarka tignoolajiyada, tollaynta ku jirta Dhuumaha Alloy Steel ERW si weyn ayaa loo dhimi karaa iyada oo la adeegsanayo daawaynta dusha sare, sida in ay ahaato mid aan la arki karin indhaha bini'aadamka.

Alloy Steel Tube & Qeexidda Dhuumaha (Lax-la'aanta/Welded/ ERW)

| Tilmaamaha | ASTM A335 ASME SA 335 |

| Heerka | ASTM, ASME iyo API |

| Cabbirka | 1/8" NB TO 30" NB IN |

| Cabirka Tuubooyinka | 1/2" OD ilaa 5" OD, dhexrooryada kastamyada sidoo kale waa la heli karaa |

| Dhexroorka dibadda | 6-2500mm; WT: 1-200mm |

| Jadwalka | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Darajo | STM A335 Gr. P5, P9, P11, P12, P21, P22 & P91, ASTM A213 - T5, T9, T11, T12, T22, T91, ASTM A691 |

| Dhererka | In ka badan 13500 mm |

| Nooca | Xumaan la'aan / La farsameeyay |

| Foomka | Wareeg, Hydraulic IWM |

| Dhererka | Hal Random, Laba Jibbaar random & Dhererka gooyay. |

| Dhammaad | Dhammaad cad, Dhammays tiran, la tuntay |

Noocyada Alloy Steel Tubooyinka Xirmooyinka

15cr mo aluminium tuubooyinka birta adag

25crmo4 aluminium bir bir ah

36 inch ASTM A 335 Fasalka P11 aluminium galvanized tube steel

42CrMo/ SCM440 bir daawaha birta ah ee aan sinnayn

Alloy 20/21/33 birta birta ah

40MM Dhuumaha birta aluminium

ASTM A355 P22 Dhuumaha Biraha Daawaha ah ee aan Xumaan lahayn

ASTM A423 Alloy Steel Dhuumaha aan Xumaan lahayn

Dhuumaha birta dahaarka hoose ee galvanized

Alloy Steel ERW Tubooyinka Guryaha Kiimikada

| Alloy Steel | |||||||

| C | Cr | Mn | Mo | P | S | Si | |

| 0.05 - 0.15 | 1.00 - 1.50 | 0.30 - 0.60 | 0.44 - 0.65 | 0.025 max | 0.025 max | 0.50 - 1.00 |

Astaamaha Makaanikada Alloy Steel Chrome Tubooyinka moly

| Xoogga Jilbaha, MPa | Xoogga Wax-soo-saarka, MPa | Kordhinta, % |

| 415 min | 205 daq | 30 daqiiqo |

Dhexroorka ka baxsan & dulqaadka ASME SA335 Alloy Pipe

| ASTM A450 | Kulul duuban | Dhexroorka ka baxsan, mm | Dulqaad, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Qabow barbaro | Dhexroorka ka baxsan, mm | Dulqaad, mm | |

| OD.25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1|OD#50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| ASTM A530 & ASTM A335 | NPS | Dhexroor ka baxsan, inji | Dulqaad, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ± 1% |

Alloy Steel Fasalka Tubooyinka Daawaynta Kulaylka

| P5, P9, P11, iyo P22 | |||

| Darajo | Nooca Daawaynta Kulaylka | Caadiyan Xadka Heerkulka F [C] | Hoos-u-dhigista ama xanaaq Heerkulka Rajada F [C] |

| P5 (b,c) | Anneal buuxa ama is-thermal | ||

| Caadiye oo xanaaq | ****** | 1250 [675] | |

| Anneal Subcritical (P5c kaliya) | ****** | 1325 - 1375 [715 - 745] | |

| P9 | Anneal buuxa ama is-thermal | ||

| Caadiye oo xanaaq | ****** | 1250 [675] | |

| P11 | Anneal buuxa ama is-thermal | ||

| Caadiye oo xanaaq | ****** | 1200 [650] | |

| P22 | Anneal buuxa ama is-thermal | ||

| Caadiye oo xanaaq | ****** | 1250 [675] | |

| P91 | Caadiye oo xanaaq | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Demisay iyo xanaaq | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

Alloy Steel Tubooyinka Codsiga Warshadaha

● Shirkadaha Shidaalka qodaya ee xeebaha ka baxsan

● Koronto abuurista

● Kiimikada batroolka

● Habaynta gaaska

● Kiimikada gaarka ah

● Daawooyinka

● Qalabka dawooyinka

● Qalabka Kiimikada

● Qalabka Biyaha Badda

● Kuleylleyda

● Condensers

● Warshadaha saxarada iyo warqadaha

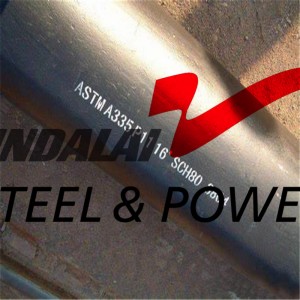

Sawir faahfaahsan

-

4140 Alloy Steel Tube & AISI 4140 Pipe

-

ASTM A335 Alloy Steel Pipe 42CRMO

-

A106 GrB Tuubooyinka Birta ah ee aan Xirnayn

-

A53 Gouting Steel Dhuumaha

-

API5L Dhuumaha Birta Kaarboon/ ERW Pipe

-

ASTM A53 Fasalka A & B Steel Pipe ERW Pipe

-

Dhuumaha FBE/tuubo bir ah oo dahaarka leh

-

Dhuumaha birta ee saxda ah

-

Dhuumaha kulul ee birta galvanized / GI Pipe

-

Dhuumaha birta ee SSAW / Dhuumaha alxanka ee Spiral

-

Dhuumaha birta aan lahayn